Telecaster Electric mandolin

Telecaster Electric mandolin

Table of contents :

4 strings “Telecaster” electric mandolin

Modeled on the famous Telecaster guitar from Leo Fender, here is the

“Teledolin”.

It is an electric mandolin, 4 strings, taking on a reduced scale, the

characteristics of an original Telecaster guitar.

- Body made of solid ash.

- Maple neck and fingerboard.

- Scale is 354 mm.

- 4 strings tuned G3, D4, A4, E5, gauge 40W, 26W, 15, 11

- Custom Pickups from ALMUSE

- Custom hardware made by myself out of brass and nickel plated, in order

to respect the general size ratio of the instrument.

Exclusive: An integrated wireless module “WS-20” by Rowin, for wireless connection to the amp.

Here are some sound clips, without any transformation, the instrument just finished:

- Neck Pickup, alone :

- Bridge pickup, alone :

- Both pickups :

Making the body

×

- 1 -

|

Two parts body, solid ash.

—|—

- 2 -

|

The templates from the plan, the body, the neck and fingerboard.

- 3 -

|

Templates for the carved cavities. No plastic pick-guard plate here, so the cavities are limited to a minimum.

- 4 -

|

Neck assembly before contouring.

- 5 -

|

Tight fit.

- 6 -

|

Cavity at the back for the wireless adapter. Drilling the hole connecting the controls cavity.

- 7 -

|

Cross drilling by the jack hole, connecting the controls cavity down to the pickup cavity.

- 8 -

|

The wireless module in its housing, which will be closed by a thin wooden lid, hold in position using 8 small magnets.

- 9 -

|

Inlaying a small steel plate in the thickness of the lid, for holding the magnets. Using my router plane.

- 10 -

|

Just a millimeter deep.

- 11 -

|

The cover (scraping still glued paper template)

- 12 -

|

True oil finish, twenty thin layers.

- 13 -

|

Copper shielding of all cavities except the one for the wireless adapter.

Hardware and pickups

- 1 -

|

Brass tailpiece blank (thank you Pete Malinson!)

—|—

- 2 -

|

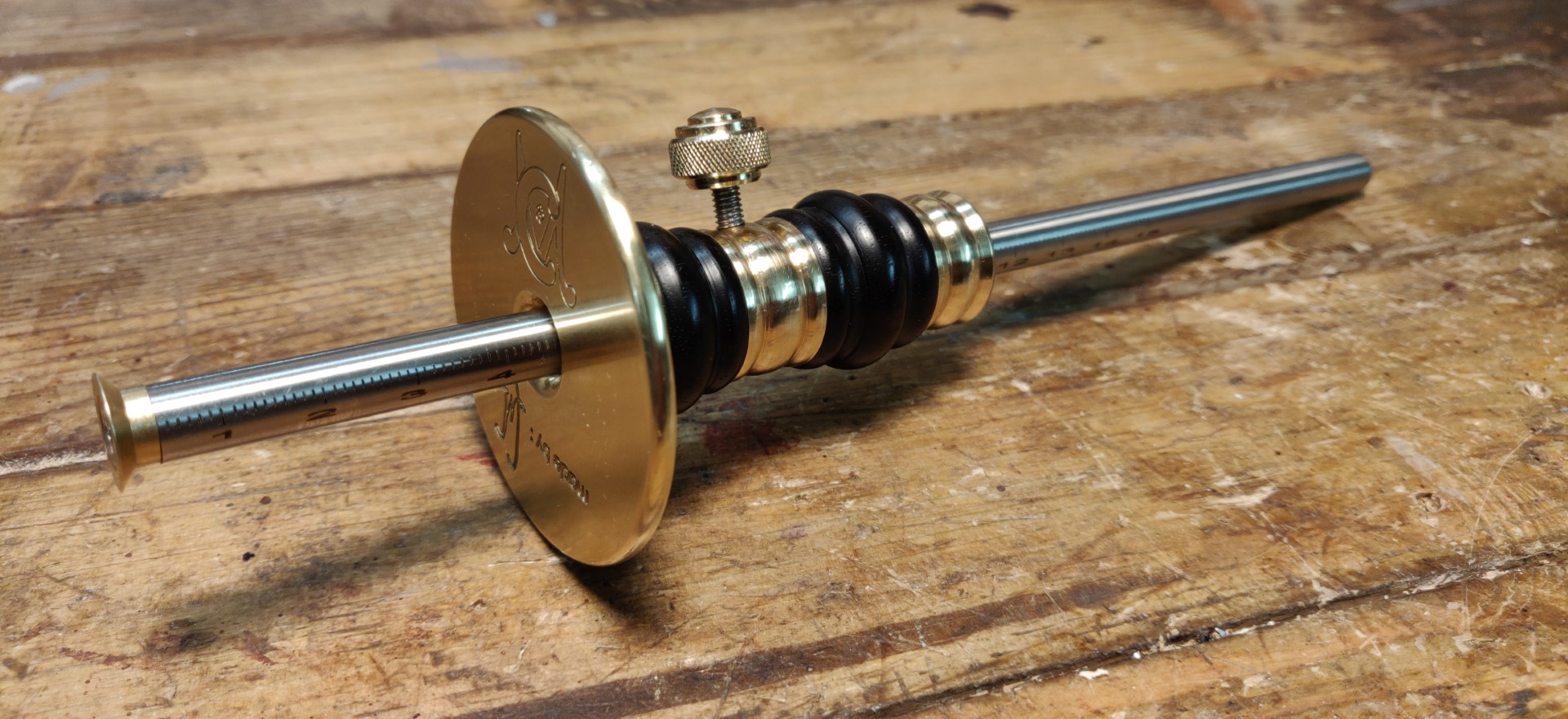

String ferrules, homemade out of brass.

- 3 -

|

The ferrules are inserted in a flat bottom hole, so as to better transfer the strings energy to the body of the instrument.

- 4 -

|

Modifying ukulele tuning machines. Milling the ends.

- 5 -

|

This leaves just enough room to put the two screws.

- 6 -

|

Preparation for nickel plating of the sleeves and the heel plate.

- 7 -

|

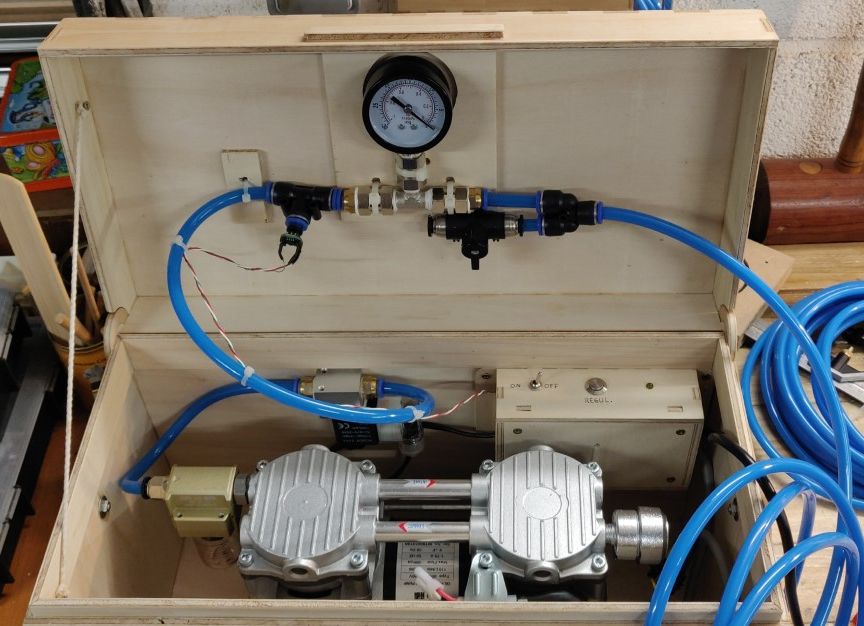

Homemade Nickel Plating setup, see this article for more information.

- 8 -

|

The finished pieces after polishing.

- 9 -

|

Installing the neck pickup.

- 10 -

|

The pickup cover locked around the microphone using insulation tape.

Making the neck and fingerboard

- 1 -

|

Template for the profile, which will be cut on the band saw.

—|—

- 2 -

|

Sanding curved parts with the sanding cylinder.

- 3 -

|

The neck cutout fit to the body.

- 4 -

|

Shaping the neck, using a rasp and file.

- 5 -

|

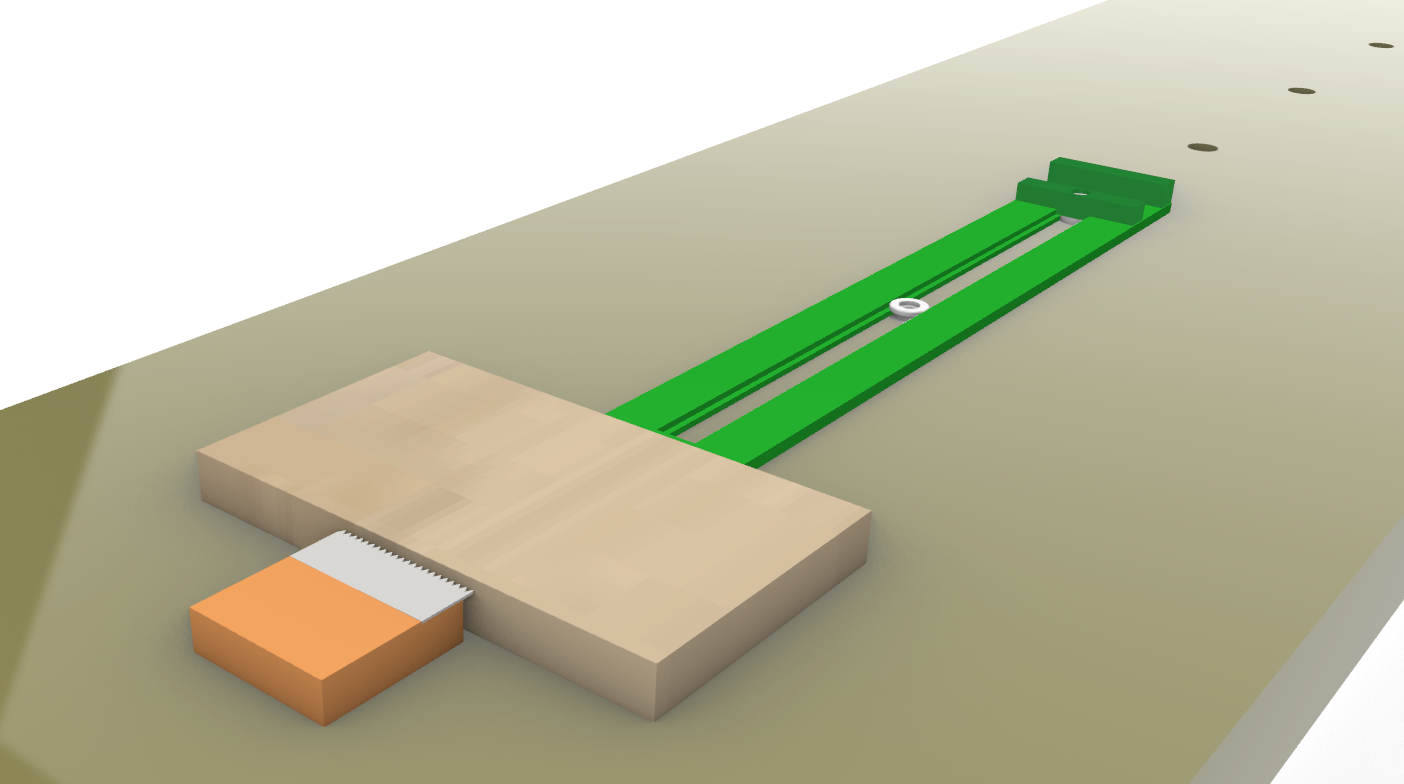

The fret slots are cut before cutting the contour.

- 6 -

|

Sanding the contour.

- 7 -

|

Gluing the fingerboard to the neck using hide glue.

- 8 -

|

Adjustment after final sanding and gluing.

- 9 -

|

Sanding to 600 grit.

- 10 -

|

Tuning machines placement.

- 11 -

|

Installation of the tuning machines.

- 12 -

|

Installing the frets.

- 13 -

|

Filing the fret ends.

- 14 -

|

Glass caul for leveling the frets. 1000 grit paper.

- 15 -

|

Leveling.

- 16 -

|

The frets have still to be crowned and polished. The fingerboard was oil finished before fretting.

- 17 -

|

Finished frets. Some additional layers of oil have been added after fretting.

- 18 -

|

My personal logo design, inspired by Fender signature. Waterslide decals between True Oil layers.

I hope you enjoyed this instrument, you can also view the making of my other

string and wind instruments on this site.

I recall that I do not sell my instruments.

You can send me your comments by responding to this article below or on my facebook page.

Christophe

Older readers comments