Scraping plane

Scraping plane

Table of contents :

Scraping plane

Here is a metal scraping plane that I made, based on a standard Stanley No4 plane.

The scaping plane is a kind of plane very useful on difficult woods like very hard woods, highly figured woods or end grain woods.

I had in my shop a plane that was of no use for me, it was an awful Asian copy of a Stanley N°4. The idea came to me to salvage the sole, as well as some other parts, in order to make a new scraping plane.

You will find, at the bottom of this article, some pictures and explanations showing how I did proceed.

The finished plane, in pictures :

[](Rabot_racler_HD_02.jpg) [](Rabot_racler_HD_03.jpg) [](Rabot_racler_HD_05.jpg)

Example on particularly tough woods :

Anigre, well figured :

Macassar ebony :

And here is how I made this plane :

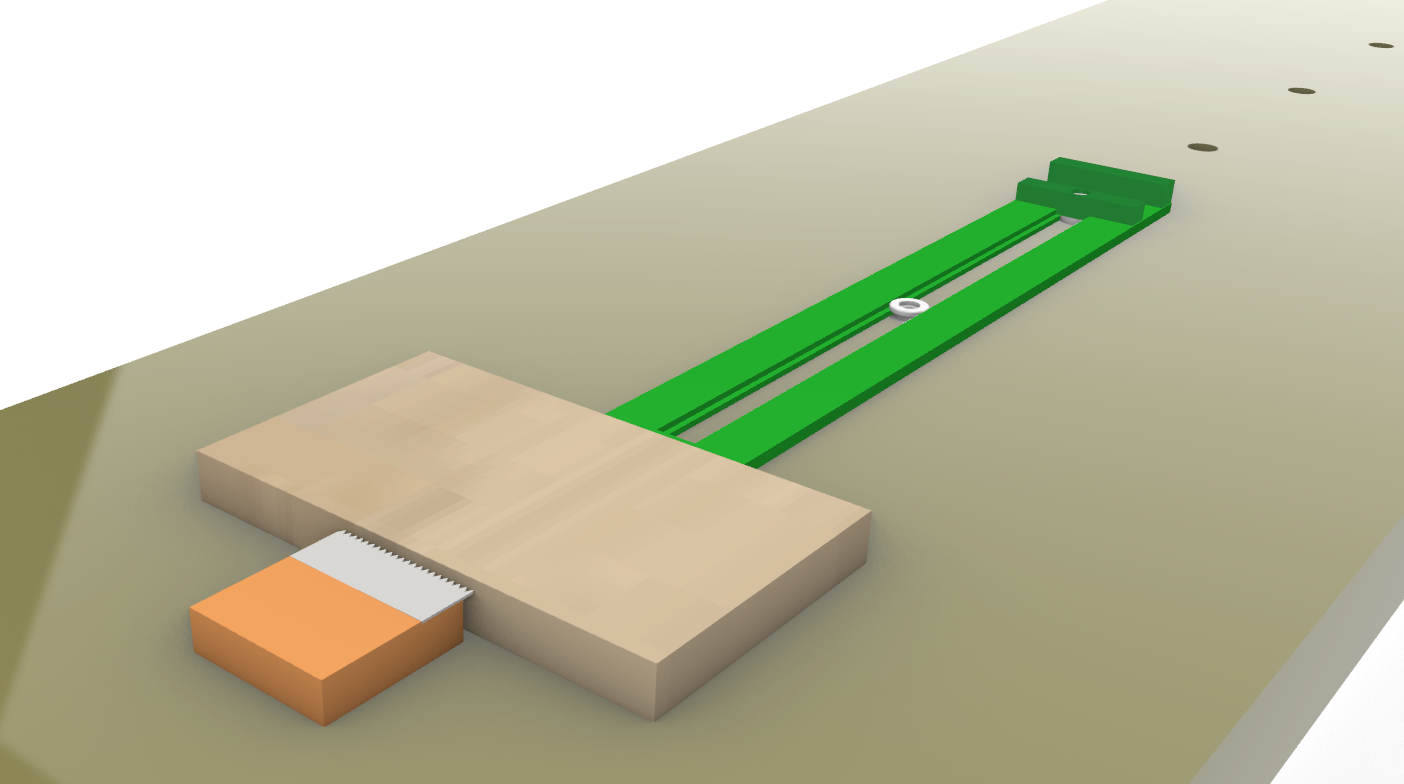

Milling the inner part of the salvaged sole.

|

Drilling holes in the inner sole in order to be able to fix the vertical element.

|

The blade support block. Here drilling the pivot holes.

—|—|—

Marking the location of the pivots on the sole.

|

The blade support angle can be adjusted and can go beyond 90°.

|

Fixing the supports for the transversal bar that will hold the blade. The wedge is salvaged from the Stanley, but the cam lever will be replaced by a button.

The bar in place (stainless steel, for more stiffness).

|

Dry set up.

|

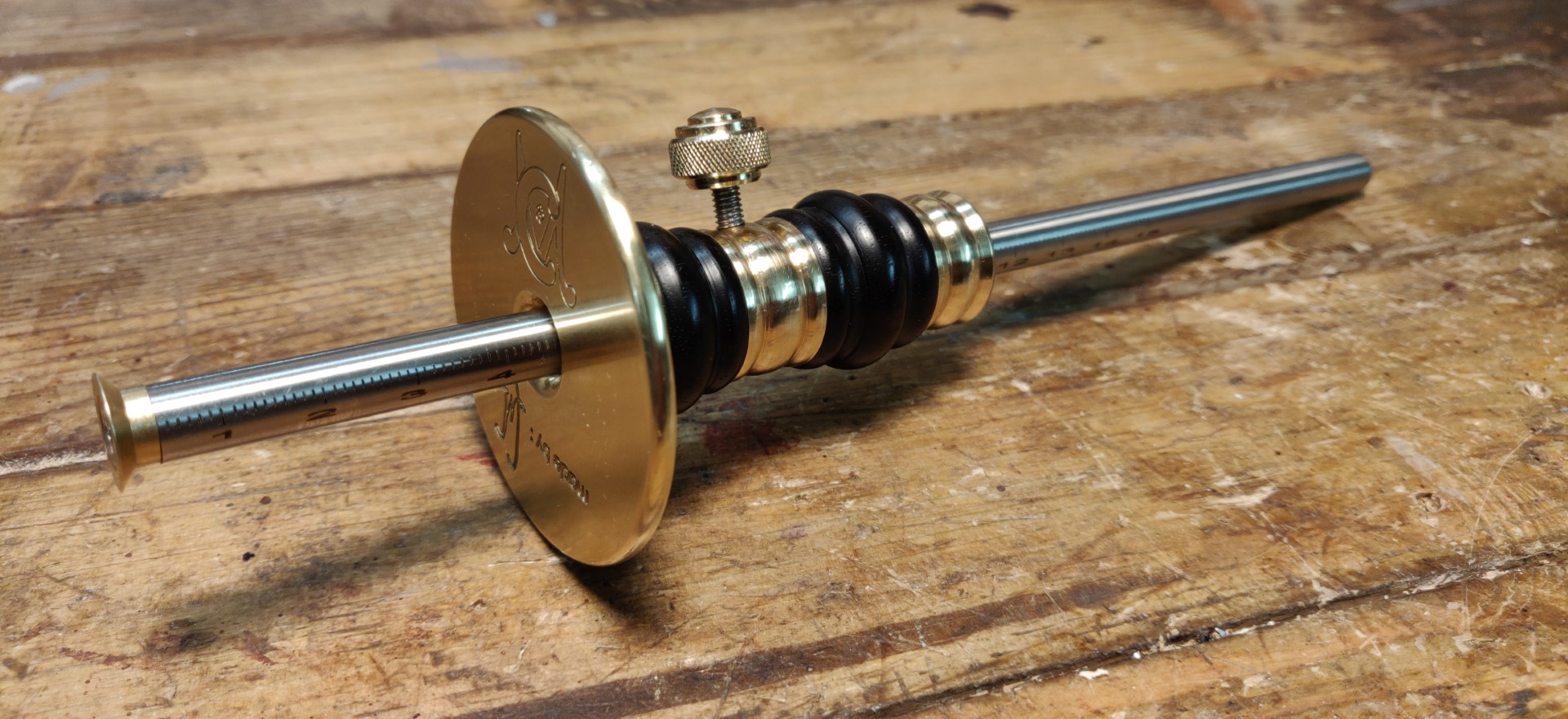

Making a brass button. For metal “savings”, the knob is done separatly from the screw.

My old engineering professor would have called that an installation “between the skin and the flesh”

|

Cutting what goes over and a small recess …

|

…in order to fit a nice rosewood turned button.

First try. On a block of end grain ebony… The mouth will have to be opened wider in order to let the shavings go out. You can see the old ugly handles, they will have to be replaced as well.

|

Zooming in on the couple of knobs that will serve for setting up and locking the blade angle.

|

Roughing out the rear handle, out of Macassar Ebony.

I need to mill the bottom in order to fit the shape of the sole.

|

The long tilted hole, for holding down the handle on the sole, has been drilled first. The rest of the shape has been centered around that hole, and not the reverse.

|

Quickly roughing out the handle with the big blacksmith rasp. Half finishing then with the hand stitched rasp.

Finishing with scrapers.

|

Carving the fore handle.

|

Scraping.

Installing the handles. The front handle must go far beyond the sole, much more than the original handle. This is because of the blade that also needs to go much more forward than the Stanley N°4.

|

The handles will be hold down using new brass nuts screwed on the original studs.

|

End here is the finished plane, seen under all angles :

Please, feel free to leave me any comment here, or on Facebook, or yet on HomemadeTools.

Christophe

Older readers comments