Scratch stock

Scratch stock

Table of contents :

Scratch stock

On the occasion of an important project of antique furniture restoration, I needed to remake missing moldings, having only a few vestiges left from the original moldings.

Two

main possibilities exist to manufacture moldings:

- You can work with a power shaper, making your irons on purpose. I personnaly do not own this machine and I am not really attracted to this kind of machine.

- You can also choose the hand work, and in this case there are also two possibilities :

The scratch stock is a tool that may be considered as outdated, one will often prefer to use a power router now, but it does have however many advantages. Besides the fact that it makes no noise or dust, it brings, compared with the router, great flexibility to shape at will any profile.

The scratch stock is a tool that works by scraping. The iron is brought to 90 ° with respect to the wood grain, it should be held in a tool holder which should be rigid and have a good grip. The molding is obtained by alternately pushing and pulling the tool on the timber, along the edge of the workpiece.

It is a tool that has been used for a long time, and remains unbeatable in certain situations, for example in cabinet making, to make a decoration on the edges of an arched cabinet foot.

The irons are shaped to measure, according to the profile to achieve, from spring steel. In my case, I use pieces of an old industrial bandsaw blade.

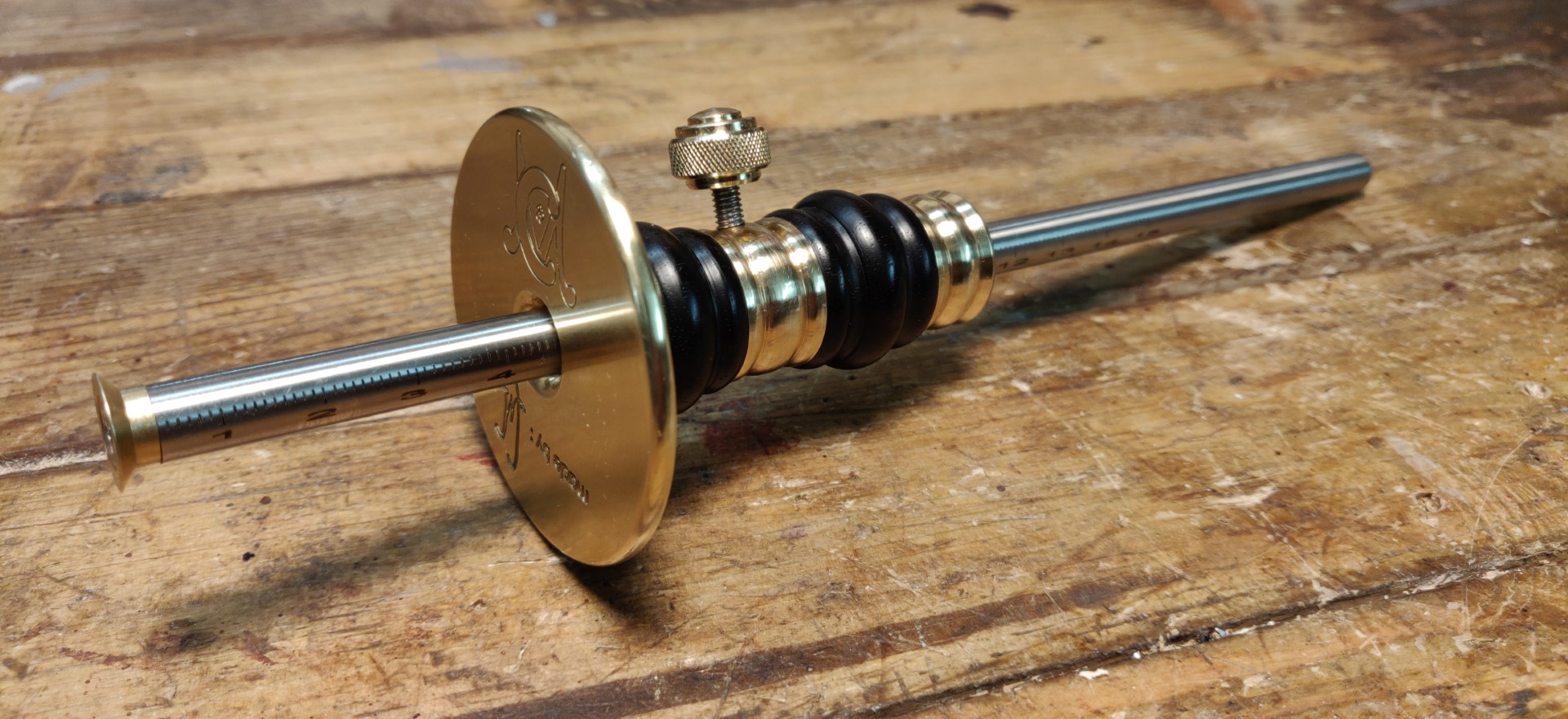

The version I have chosen to make is inspired by a commercial tool with a metal body and two asymmetrical handles.

The design is very simple,the sole is a corner piece, relatively thick. The vertical face has an iron plate against which grips the iron by means of two screws. For simplicity, these are the same screws that clamp the iron and allow to lock both handles in place.

The tool operates on the edge of the workpiece, one of the two handles is therefore in the air, while the other handle is above the workpiece. This is why the handle which is “in the air” has a shape similar to a chisel handle, so that you can grip it like a bike handlebar. The other handle is more similar to a plane front knob.

Both thumbs are pressed against the iron plate.

Front and rear views :

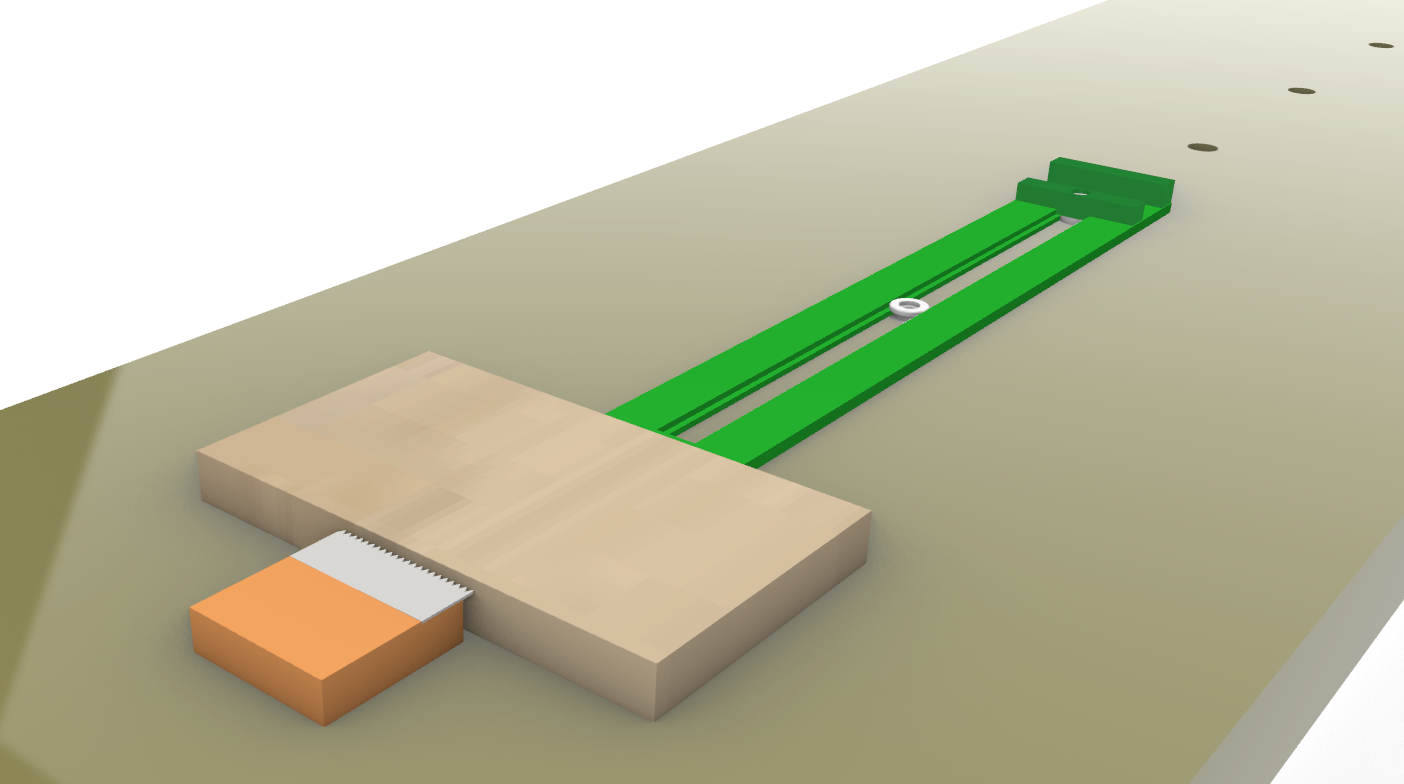

The parallel guide is in fix position. It is the blade that can be set up more or less close to the fence.

I have made a ball bearing guide, in order to follow any curved edge, and also a straight fence, in order to follow straight edges.

The straight fence has a little notch, in order to provide room for the iron :

The scratch stock in working position :

And the result, on cherry wood :

Here are some details on the making of this tool, as well as how the iron is shaped :

The metal parts before assembly. The shafts for the handles a turned out of

brass on the metal lathe in three different pieces, then silver brazed.

The steel corner piece is an assembly of two different pieces, welded

together. The sole is 5mm thick, so that the there will have enough threads on

the threaded hole that will serve to fix the parallel guide.

|

The shafts, after brazing and polishing.

|

The handles are made of cherry wood, stained and oil finished.

—|—|—

Making of the iron. Starting from an actual molding, I trace on paper the heights and widths of the different intersection points of the profile. I then copy the profile on a piece of saw blade for which I have ground the teeth and polished the faces.

|

The profile is rough cut with a Dremel disk.

|

It is then finished using small needle files. The cut must be clean and well orthogonal. There is no bur on this kind of scraper.

Moldings made with the iron above.

| |

And here is a video showing the making of a molding strip with this tool. The fist part shows some agressive cuts, roughing out the profile, and the second part shows some finishing cuts, the goal is to polish the surface in order to avoid any sanding.

Please, feel free to leave me any comment here, or on Facebook, or yet on HomemadeTools.

Christophe

Older readers comments

Hello from Papy1958