Cordless drill corded

Cordless drill corded

Table of contents :

Cordless drill made CORDED

I don’t know if you are like me, but each time I need to use a cordless tool, it is always exactly when its batteries are dead flat… and I only have to wait for at least one hour to be able to use it again.

But, personally, I rarely schedule in my agenda the use of my tools, and thus, I make very little use of my cordless drill, for that reason.

Moreover,

I have found a good alternative to the cordless

screwdriver, it’s simply a brace and screw

driver bit, instead of a drilling bit. You have the torque, the slow speed,

the control, only the dimensions can be a drawback…

Moreover,

I have found a good alternative to the cordless

screwdriver, it’s simply a brace and screw

driver bit, instead of a drilling bit. You have the torque, the slow speed,

the control, only the dimensions can be a drawback…

I have always wondered why the power tool manufacturers have never thought about a workshop version of the power screwdriver, in particular with the torque limiter. When you are in your workshop, the cord may not be a big drawback, compared to the tool readiness, and full power you can gain with the mains power. It should be a valuable feature for a tool to be able to be both mains and battery powered.

And eventually, that’s the result I obtained with the modification I propose hereafter.

We can find a lot of howtos over the Internet showing cordless drills modifications, operating with an adapter, mostly plugged in a wall socket or using a laptop computer power block. The main drawback of these solutions is that, if they can make the drill spinning without any problem, they will certainly not be able to sustain the maximum torque load, which necessitates a lot of current. This can be in the magnitude of 10 A (low voltage).

It’s not very simple to find a low voltage power supply with high amperage. Except the car battery charger, which would not be a very elegant solution, I could not find until now a good, affordable solution.

After some research and discussions, it appears that one of the most interesting DIY solutions is to make oneself a power supply, re-using a micro- wave oven transformer, which can deliver an high power output in 18V AC. You just need a 4 diodes bridge and a capacity to redress the current, all that components being properly sized to support the ten amperes.

But, I ended up finding the Graal ! One can find nowadays, in some specialized shops, stabilized power supplies, 12 V and high amperage, made for powering some kind of big LED string ribbons. There is a full range, and the most powerfull I saw could reach 360W, which is 30 amperes !

I went for a 240 Watts model, with all the features I’ve always dreamed about :

- stabilized (it will be used for a lot of other things than the corded drill)

- 12V / 240 W , so 20 amp max.

- ventilated.

- Protected against over-voltage and over-current.

- relativly compact, designed to be installed on a wall, even outdoor.

- Moderate price : only 33€ on eBay.

So I had three problems remaining :

- Tension : the drill is originally 14.4 V, whereas the power supply is 12V :

Actually, DC motors are really tolerant of the tension applied to them. You can without any problem power them with a lower and even a higher tension compared to their original battery voltage.

In my case, the batteries, that I still wish to make use of, are 14.4 V. The

drill works perfectly fine powered with 12V. The rotation speed is slightly

lower than with 14.4V (with fully charged batteries), and it does not decrease

because the power supply is stabilized to 12V. The tension will not decrease

when the current will increase (in the limit of the max 20A

). In fact, the torque should theoretically

be greater with the power supply than with the battery, in spite of the 2.4 V

difference.

). In fact, the torque should theoretically

be greater with the power supply than with the battery, in spite of the 2.4 V

difference.

- The cord

I wanted to find some supple and soft cable that could carry a high amperage. I chose to use HI-FI speaker cable. It has a 3.5 mm2 section (traditionally, 1mm2 is required for 10A).

- The connection with the drill

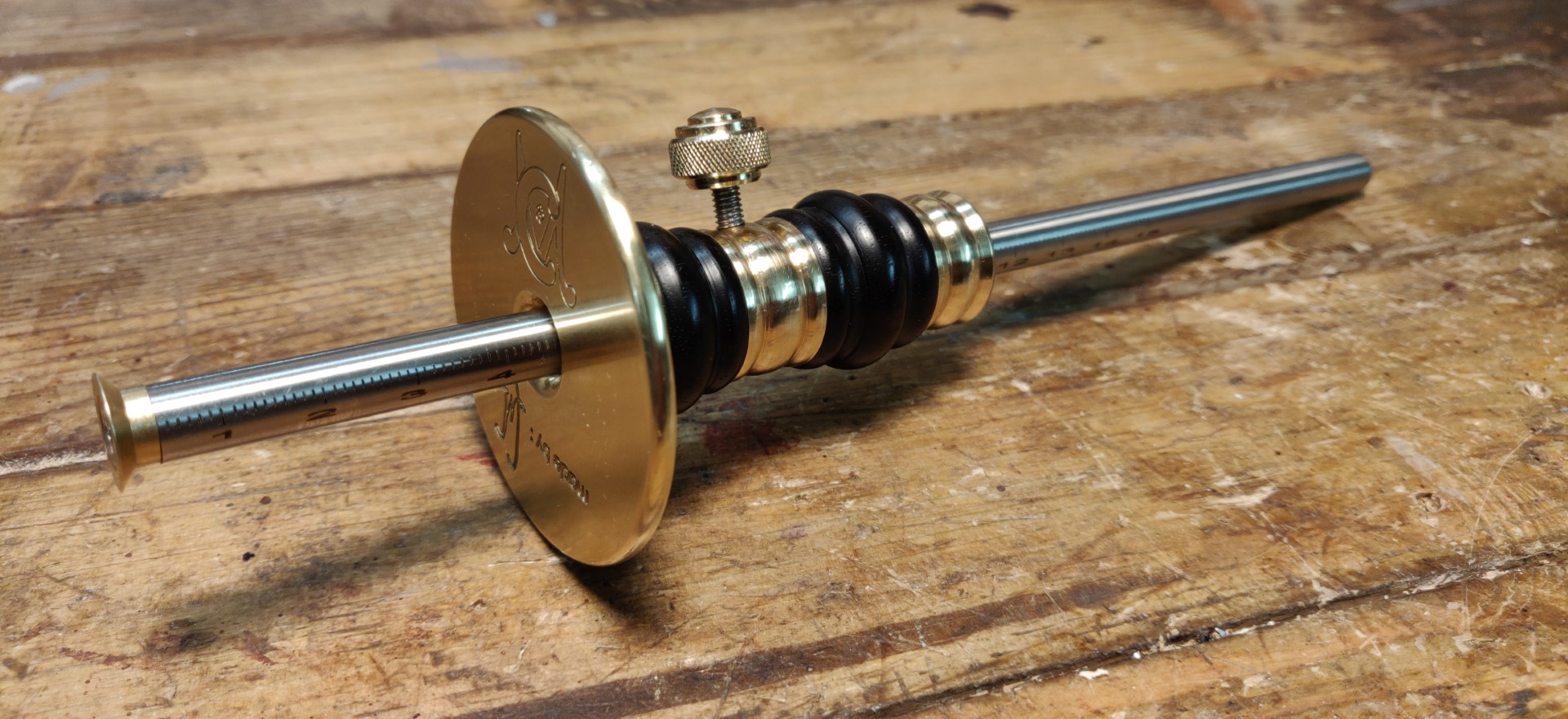

The most common solution found over the net is to reuse an OOO battery pack.

In my case, my battery packs still work fine, thus I preferred to make a

custom adapter, from wood and brass ( ).

).

Here are some details showing the making of this connector and its wiring.

1- A piece of ash, with identical section as the male part of the battery pack. Two brass tabs for making contact with the the connectors inside the drill handle.

|

2- The cable goes through the height and gets out on each side, under the tabs.The tabs are tin brazed to the cable, with a large contact area.

|

3- The brass tabs are inlaid in the wood and locked with a couple of brass pins (shortened!)

—|—|—

4- The connector is hold in place thanks to a rubber bracelet.

|

5- Taking care to polarity.

|

6- Of course, the battery pack is still usable, no intrusive mod.

And here is a video showing a demo of the corded cordless drill

, see the speed

and torque :

, see the speed

and torque :

Have fun !

Feel free to leave a comment, here or on Facebook, or on HomemadeTools.

Christophe

Older readers comments

Hello from jcfr67