Toothed blades

Toothed blades

Toothed blades for finger planes

Highly figured woods like curly maple or some burled woods are very difficult to work.

The grain direction always changes, and planing such wood often leads to some tearing out.

For a roughing work, like we always do for the curly maple violin backs, after the gouging, we can use some plane blades that have tooth which prevent the production of a long and wide chip.

The chips with this kind of blade are rather short and look like some kind of

little curly spaghettis  .

.

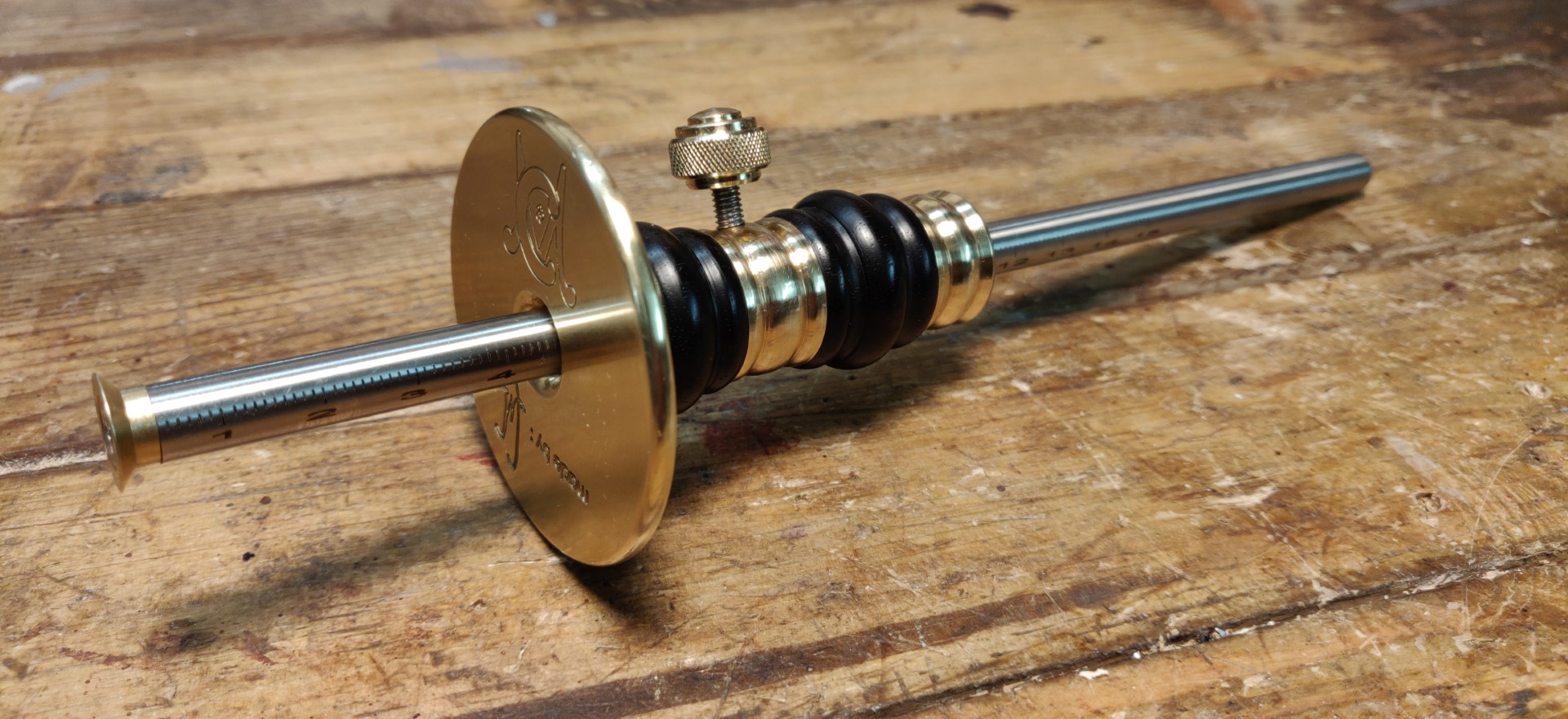

Here is a little article showing how I have built a set of blades with different widths for my brass finger planes, starting from a standard large plane blade I purchased for that purpose.

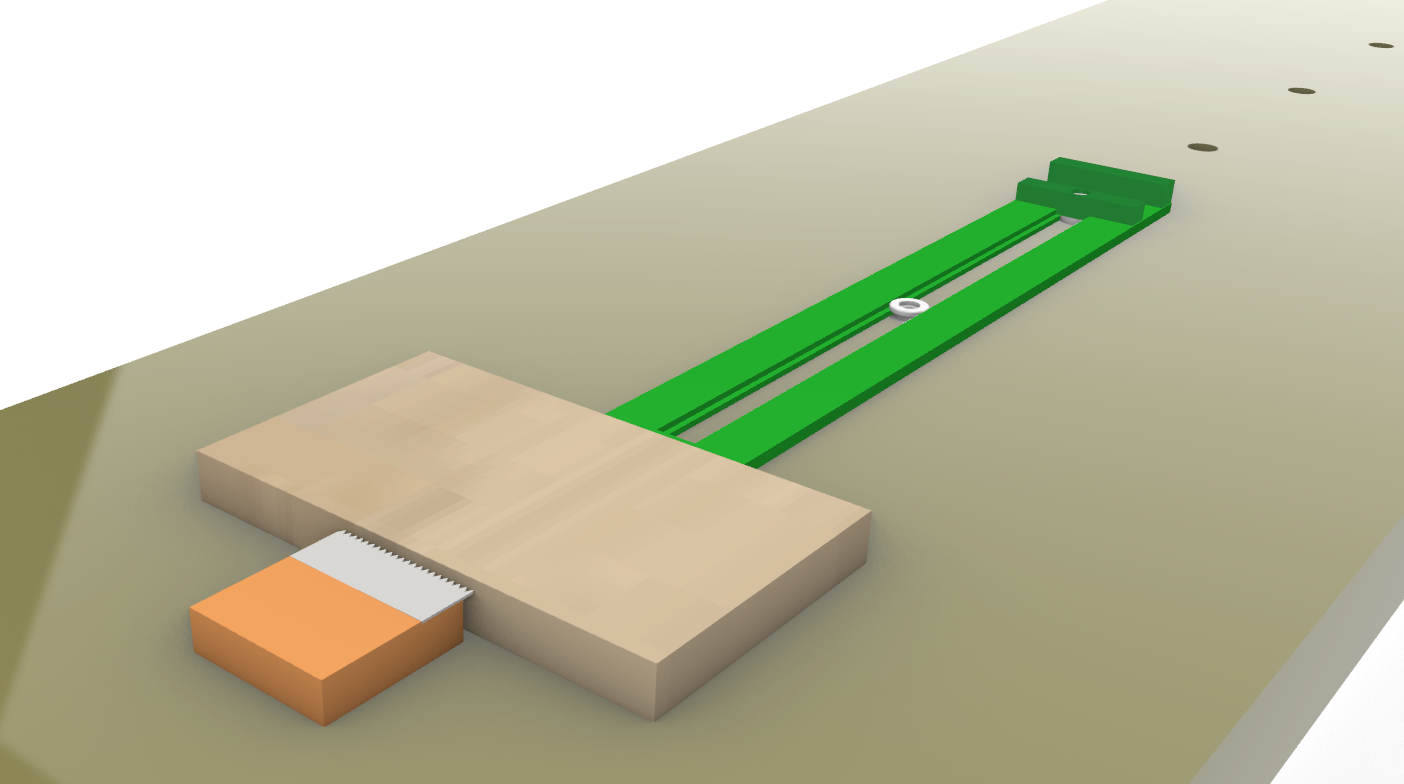

Drawing the contours of the four blades, taking the original blades as a model. I want to keep them with no tooth.

The blades are then cut using an angle grinder.

It is really important to very often soak the piece into water for cooling it, in order to avoid loosing the temper of the blade.

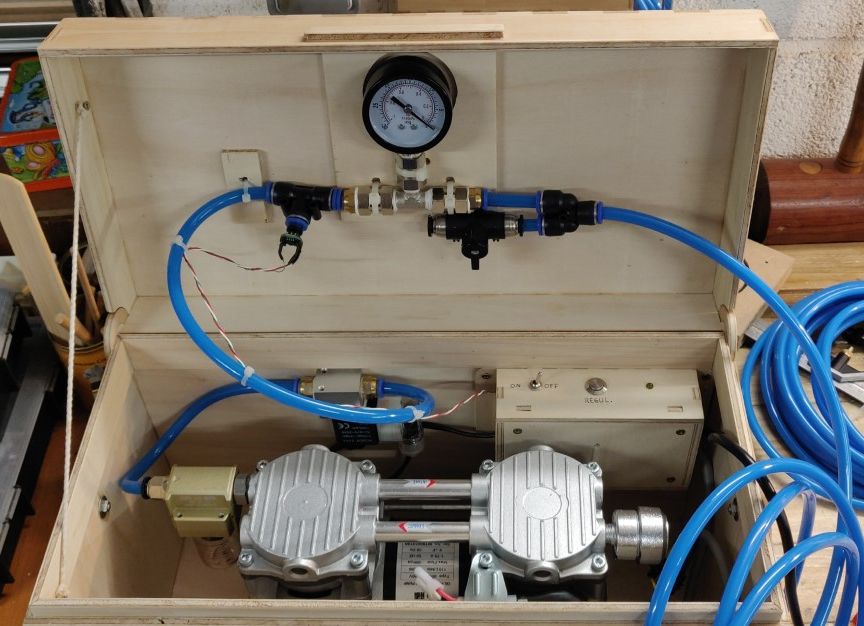

I use my metal lathe in a particular milling configuration:

- The piece is hold in the chuck, which is blocked. It only acts as a vise.

- A “miiling square fixture” is mounted on the carriage. It holds the Dremel installed with a thin cutting disk.

- The milling fixture adds to the x,y lathe axis (longitudinal, transversal) a z vertical axis allowing to setup the depth of the cut of the grinder.

- The cooling, not shown here, is done using the air compressor.

One pass was enough for one groove. The pre-drawing allows to space evenly the different grooves.

And here is a set of blades for the different widths.

The sharpening is quite difficult. I did it by hand using the water grinder.It must follow the curve of the sole.

The blade, properly set, must show just enough and evenly on the full width of the plane.

Comments are welcome !

Christophe

Older readers comments